A few months ago, I was sitting at an airport, watching airplanes take off and land. Like most people, I used to think about big things—engines, wings, cockpits. But that day, I started wondering: what about the small parts inside these planes? There’s a whole world of tiny components that play an essential role in aviation, many of which go unnoticed by the general public. That’s when I came across a component named d243w003-2.

At first, the name sounded like a boring code. But the more I read about it, the more I realized how important such small parts are in making airplanes safe and efficient. In this article, I want to share what I learned—mixed with my personal experience as someone who got genuinely fascinated by this tiny, powerful piece.

What Is the Boeing D243W003-2?

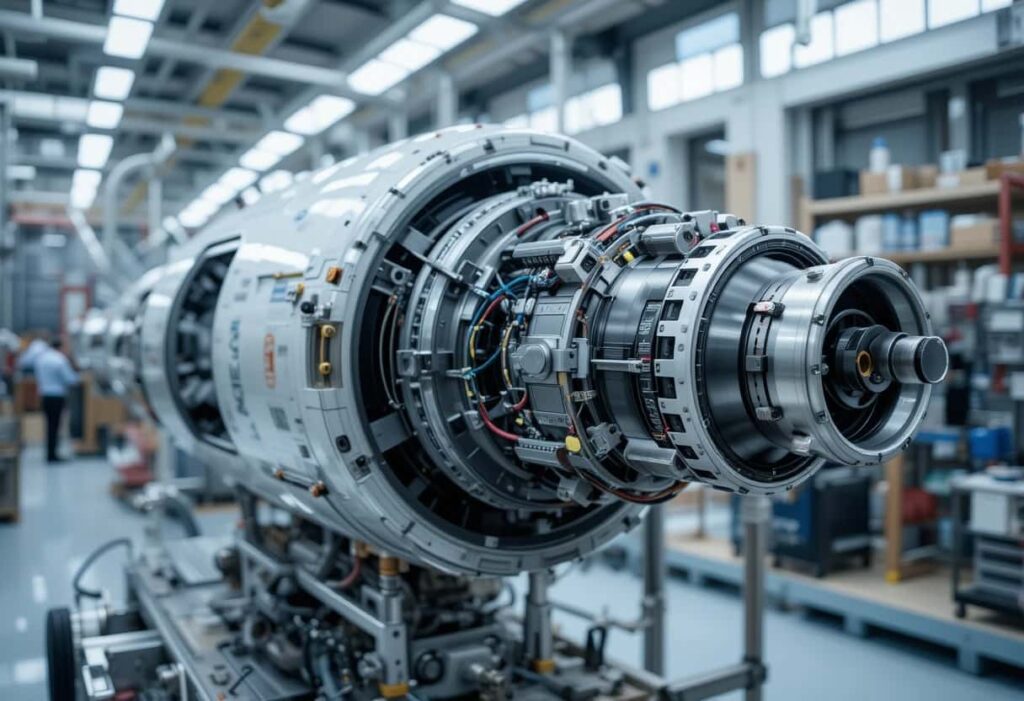

The Boeing D243W003-2 is a critical aircraft component, likely serving in electrical, fuel, or control systems. While Boeing keeps exact details confidential, aviation experts suggest it could function as a wiring harness connector, sensor module, or control system interface. These small yet essential parts ensure smooth communication between different aircraft systems, enhancing safety and operational efficiency.

Designed to withstand extreme flight conditions, the D243W003-2 plays a vital role in maintaining the reliability and performance of modern Boeing aircraft. Its precision engineering and rigorous testing make it a key element in Boeing’s commitment to aviation safety. The component’s durability and consistent performance contribute significantly to reducing maintenance needs and improving overall aircraft longevity.

The Discovery of Something Small Yet Powerful:

That day at the airport wasn’t anything special. I was just waiting for my flight with some time to kill. I opened my laptop and started reading a blog about how airplanes are built. I’ve always had a curious nature, especially about how things work. My attention stopped at a short mention of d243w003-2, which was described as one of Boeing’s internal components. It didn’t have any pictures or long descriptions, but it made me pause.

Why? Because this was the kind of thing I never thought about before. Most people admire the massive wings or the engine roar when a plane takes off. But this was different—a hidden component, working quietly and tirelessly, yet so important.

Features of the D243W003-2:

The D243W003-2 is designed with several key features that make it an indispensable part of modern aircraft systems. These features include:

- Compact Design: Despite its small size, the D243W003-2 packs a lot of power and functionality into a compact frame, which is crucial in the highly constrained environment of an aircraft.

- Advanced Materials: Made with high-quality alloys and composites, this part is lightweight but incredibly durable. The materials used are resistant to the extreme pressures and temperature fluctuations experienced during flight.

Precision Engineering: Every detail of the D243W003-2 is meticulously crafted to meet Boeing’s exacting standards for performance and safety. This precision ensures that the part integrates seamlessly into the aircraft’s complex systems. - Durability: The D243W003-2 is built to last, withstanding not only the routine wear and tear but also the extreme conditions that aircraft face, such as turbulence, temperature shifts, and the constant vibration of flight.

Why Is the D243W003-2 So Important?

Ensures System Reliability:

The D243W003-2 keeps aircraft systems working smoothly. Planes use thousands of connected parts, and this component helps maintain strong electrical or data links. By preventing connection failures during flight, it ensures all systems communicate properly. This reliability is crucial for safe operations, reducing the risks of mid-flight issues that could affect performance or safety.

Built for Extreme Conditions:

Aircraft face harsh environments—extreme heat, cold, pressure changes, and vibrations. The D243W003-2 is specially designed to handle these tough conditions without breaking down. Boeing engineers test it rigorously to ensure it stays strong and functional, no matter the challenges. This durability keeps flights safe and on schedule.

Enhances Fuel Efficiency:

The D243W003-2 uses lightweight but strong materials, helping reduce the plane’s overall weight. Less weight means the aircraft burns less fuel, saving costs and lowering emissions. In modern aviation, every bit of efficiency counts, making this component a key player in greener, more economical flights. It’s smart design supports both performance and sustainability.

Also read: Tiuqyazhmizz – Everything You Need To Know About This Powerful System!

Materials and Engineering Behind the D243W003-2:

Boeing uses advanced materials to craft high-performance components. The D243W003-2 likely includes:

- Titanium alloys: give the D243W003-2 incredible strength while fighting rust and wear. These metals handle extreme pressures without bending or breaking, making them perfect for critical aircraft parts that must last through thousands of flight hours in tough conditions.

- Carbon fiber composites: make the part super light but still tough. This space-age material helps planes save fuel by reducing weight while being strong enough to handle vibrations and stress during takeoff, flight, and landing.

- High-grade polymers: protect delicate electronics from heat and electricity. These advanced plastics insulate wiring and components, preventing shorts and damage when temperatures swing from freezing altitudes to hot engine areas.

- Precision engineering: means each D243W003-2 fits perfectly every time. Boeing uses exact measurements and tight quality control so these components work flawlessly with other aircraft systems.

- Extreme testing proves the part can survive real flight conditions. Before installation, components face simulated storms, temperature extremes and years of wear in just days of testing.

How Boeing Tests the D243W003-2 for Safety:

Before installation, every aircraft component undergoes rigorous testing. The D243W003-2 is likely subjected to:

Stress Tests for Extreme Conditions:

The D243W003-2 faces simulated maximum flight stresses beyond normal operations. Engineers apply intense mechanical loads to verify it won’t fail when most needed. These tests replicate years of wear in accelerated cycles, proving the component’s durability under extreme pressure while maintaining structural integrity for safe, long-term aircraft operation.

Vibration Resistance for Turbulent Flights:

Specialized shakers subject the component to violent vibrations matching severe turbulence. This confirms that electrical connections stay secure and systems remain operational during rough air encounters. The testing mimics continuous flight vibrations to guarantee years of reliable performance without loosening or malfunctioning mid-flight.

Temperature Endurance for Harsh Environments:

The component cycles between 60°C and 200°C to simulate altitude cold and engine heat. Materials and connections must maintain perfect operation through rapid temperature swings. This thermal shock testing ensures reliable performance whether cruising at high altitude or exposed to scorching engine bay conditions during takeoff.

The Role of the D243W003-2 in the Aircraft’s Systems:

The D243W003-2 serves a specific purpose in the aircraft’s broader system of control, electrical, or fuel management. Similar components are responsible for ensuring that different systems communicate with each other, such as linking the cockpit to the plane’s subsystems or managing electrical wiring. This small part helps maintain a seamless flow of communication and functionality throughout the aircraft. By ensuring that signals and data are transferred accurately, the D243W003-2 plays a pivotal role in the synchronization of vital systems. Its reliable performance is crucial for tasks ranging from managing flight navigation to ensuring the proper functioning of the power systems. Without it, even the most advanced aircraft would face communication breakdowns that could impact performance and safety.

Benefits of the D243W003-2:

The D243W003-2, though small in size, offers immense benefits that significantly contribute to the overall functioning and safety of the aircraft:

- Improved Safety: By being part of the electrical or control systems, the D243W003-2 ensures that crucial signals and data are transferred reliably. This helps maintain proper communication between the cockpit and various subsystems of the aircraft, ultimately improving flight safety.

- Enhanced Efficiency: With its role in managing electrical systems, fuel, or control modules, the D243W003-2 plays a role in making the flight more efficient. Ensuring seamless connections and data flow helps the aircraft operate at optimal performance, reducing fuel consumption and operational costs.

- Increased Reliability: The rigorous testing and high standards behind the D243W003-2’s design guarantee its reliability. Airlines and engineers can trust that this component will function under even the most stressful conditions, contributing to the overall dependability of the aircraft.

- Long-Term Performance: Due to its durability and design, the D243W003-2 has a long lifespan, meaning fewer replacements and lower maintenance costs for airlines. This is particularly important in reducing the downtime of the aircraft, allowing airlines to operate more efficiently.

The Future of Aviation and the Role of Small Components like the D243W003-2:

The future of aviation is deeply connected to the evolution of small yet powerful components like the D243W003-2. With advancements in material science, these parts will become lighter, stronger, and more heat-resistant, enhancing aircraft efficiency.

Their role in supporting automation and smart flight systems will grow, while also aiding sustainability by improving fuel usage and reducing emissions. Enhanced with diagnostic sensors, such components will boost maintenance precision. As aircraft become more efficient, lightweight parts like the D243W003-2 will be vital to progress.

FAQS:

1. What is the D243W003-2 component, and why is it important in aviation?

The D243W003-2 is a small but crucial component in aircraft systems. It plays a key role in managing electrical, fuel, or control systems within the plane. Despite its small size, it ensures seamless communication between the various subsystems of the aircraft, contributing to the overall safety, efficiency, and performance of the flight.

2. How does the D243W003-2 improve aircraft safety?

The D243W003-2 contributes to safety by ensuring smooth communication between the cockpit and the plane’s subsystems. This reliability helps prevent errors or malfunctions, ensuring that critical systems, like navigation and fuel management, operate efficiently and without interruption, which is essential for a safe flight experience.

3. What materials are used in the D243W003-2, and how do they affect its performance?

The D243W003-2 is made from lightweight, durable materials such as advanced alloys or composites. These materials ensure the component’s strength while minimizing weight, which is essential for fuel efficiency and the overall performance of the aircraft, particularly in challenging flight conditions.

4. How does the D243W003-2 contribute to aircraft maintenance?

The D243W003-2 plays a role in efficient maintenance by being part of an aircraft’s network of systems that can be monitored and checked during routine inspections. Its reliable performance reduces the risk of malfunction and the need for frequent repairs, ensuring the aircraft remains in peak condition for every flight.

5. How will the D243W003-2 evolve with future advancements in aviation technology?

With advancements in materials and automation, the D243W003-2 will continue to evolve. Future versions of this component may incorporate smarter materials, sensors for real-time diagnostics, and enhanced reliability to support more automated flight systems, leading to even safer and more efficient aircraft operations in the future.

Conclusion:

The D243W003-2 may look insignificant, but it plays a big role in the safety and performance of Boeing aircraft. Its durability, precision, and ability to withstand harsh conditions make it a vital component. Without parts like this, modern aviation wouldn’t be as reliable or efficient.

This tiny component supports smoother flights by ensuring steady system communication and reducing maintenance needs. It also contributes to better fuel efficiency, helping airlines save costs and lower emissions. Every small part like the D243W003-2, helps keep the bigger picture of aviation running smoothly.

Related post: